In the intricate realm of powder coating, the

Electric Powder Curing Oven assumes a role of paramount significance. It serves as the alchemical crucible that transmutes the powder - coated workpiece into a resilient and high - calibre finished product. Now, let us embark on a detailed exploration of this indispensable piece of equipment.

The

Electric Powder Curing Oven, a veritable marvel of engineering, is a specialized heating apparatus meticulously crafted for the singular purpose of curing powder coatings. Its construction primarily encompasses a heating chamber, heating elements, a temperature control system, and, in the case of continuous - type ovens, a conveyor system.

The heating chamber, a bastion of hermetic and insulated design, provides the hallowed space wherein the curing process unfolds. Nestled within its confines are the heating elements, typically fashioned from high - resistance alloys. As an electric current courses through these elements, they engender heat, which is then artfully and evenly disseminated throughout the chamber.

The temperature control system, a linchpin of the oven's functionality, typically comprises a thermostat, temperature sensors, and a control panel. The thermostat empowers the operator to precisely set the desired curing temperature. Temperature sensors, ever - vigilant, continuously monitor the temperature within the oven and relay feedback to the control panel. Should the temperature deviate from the pre - set value, the control panel deftly adjusts the power supply to the heating elements, thus maintaining a steadfast and unwavering temperature.

In continuous - type

Electric Powder Curing Ovens, the conveyor system choreographs the movement of the powder - coated workpieces through the heating chamber at a meticulously controlled speed. This orchestration ensures a seamless and highly efficient curing process.

These curing ovens have found their way into the heart of diverse industries, leaving an indelible mark. In the automotive industry, they are the silent artisans responsible for curing the powder coatings on car bodies, wheels, and engine components. The high - temperature and exquisitely temperature - controlled milieu they create bestows upon the coatings a remarkable strength and durability, shielding the parts from the perils of corrosion and wear.

In the realm of furniture manufacturing, metal furniture frames and decorative parts undergo a transformative journey within these ovens. The powder coating, like a magical elixir, not only elevates the aesthetic allure of the furniture but also fortifies its resistance to scratches and the vagaries of environmental factors.

In the electronics industry, the

Electric Powder Curing Oven stands as a sentinel, curing the coatings on electronic device enclosures. It serves as a bulwark against dust, moisture, and the insidious threat of electromagnetic interference.

The cost of an

Electric Powder Curing Oven is a tapestry woven from the threads of its size, capacity, and features. A petite, benchtop curing oven, a companion for small - scale workshops or enthusiastic hobbyists, may command a price in the range of $500 - $1500. These ovens, with their unadorned structure and basic temperature - control functions, offer a practical entry point.

Mid - sized industrial curing ovens, with their capacious heating chambers and more advanced temperature - control systems, occupy a price spectrum between $3000 - $8000. Tailored for medium - volume production, they proffer enhanced temperature uniformity and control accuracy, a boon for discerning manufacturers.

Large - scale, high - capacity industrial curing ovens, equipped with automated conveyor systems, multi - zone temperature control, and high - power heating elements, can soar in price upwards of $15000. These behemoths are engineered for high - volume production lines, capable of handling large - sized workpieces with aplomb.

Prior to commencing the curing process, it is incumbent upon the operator to preheat the oven to the requisite curing temperature, adhering scrupulously to the powder coating manufacturer's instructions. The powder - coated workpieces should be arranged with care and evenness within the oven, with ample space interposed between them to ensure the unfettered circulation of heat.

In the case of continuous - type ovens, the conveyor speed must be calibrated in accordance with the curing time demanded by the powder coating. During operation, the temperature and the curing process should be monitored with regularity and vigilance.

Once the curing process reaches its denouement, the workpieces should be retrieved with care, employing heat - resistant tools. It is imperative to refrain from immediately opening the oven door, as sudden temperature fluctuations can cast a shadow over the quality of the coating.

When embarking on the quest to select an

Electric Powder Curing Oven, one must take into account the dimensions of the workpieces and the production volume. For small - sized workpieces and low - volume production, a benchtop or small - scale oven shall suffice, a simple yet effective solution. However, for large - scale industrial production with voracious volume requirements, a large - capacity oven equipped with an automated conveyor system is nothing short of essential.

Moreover, the temperature accuracy and uniformity demanded by the specific powder coatings must be carefully considered. Some powder coatings, like delicate prima donnas, are highly sensitive to temperature fluctuations. Thus, an oven with precise temperature control is of the utmost importance.

Budget, too, looms large as a decisive factor. One must strike a harmonious balance between requirements and cost, seeking out the oven that best aligns with one's needs. Additionally, the reputation of the manufacturer and the quality of their after - sales service should not be overlooked.

Safety, an inviolable principle, reigns supreme when operating an

Electric Powder Curing Oven. The operator should don heat - resistant gloves and safety glasses, donning a protective armour against the perils of burns and potential splashes.

It is crucial to ensure that the oven is installed correctly and grounded securely, a safeguard against the spectre of electrical accidents. Overloading the oven is a perilous folly, as it can disrupt heat distribution and pose a fire hazard.

Regular inspections of the heating elements, temperature control system, and conveyor system (if applicable) should be conducted to detect any signs of malfunction. Flammable materials should be kept at a safe distance from the oven, banishing the risk of conflagration.

The design of an

Electric Powder Curing Oven is a paragon of rationality. The employment of electric heating elements proffers a clean and efficient heat source, a boon for both the environment and productivity. The precise temperature control system acts as a maestro, ensuring that the powder coating is cured evenly and at the optimal temperature, culminating in a high - quality finish that is the envy of the industry.

The conveyor system in continuous - type ovens is the engine that drives a continuous production process, a catalyst for increased productivity. The insulated heating chamber, like a thrifty steward, helps to conserve energy by minimizing heat loss.

Q: What course of action should I pursue if the powder coating exhibits bubbles after curing?

A: First and foremost, one should scrutinize the pre - heating process. A precipitous rise in temperature may well be the culprit behind the formation of bubbles. Additionally, it is imperative to ensure that the powder - coated workpiece is entirely free of moisture prior to curing. Adjust the curing temperature and time in strict accordance with the powder coating specifications.

A: Indeed, one can, but it is incumbent upon the operator to cleanse the oven thoroughly between different powder types. Different powder coatings, each with its own idiosyncrasies, may have divergent curing requirements. Thus, the temperature and time should be adjusted accordingly.

Q: How frequently ought I to calibrate the temperature control system of the curing oven?

A: It is recommended to calibrate the temperature control system every 3 - 6 months, with the frequency contingent upon the intensity of use. This ensures the accuracy of temperature settings, a prerequisite for consistent and reliable curing results.

Q: What steps should I take if the heating elements in the curing oven cease to function?

A: Commence by examining the power supply and the fuses. If these prove to be in order, the heating elements may have succumbed to burnout. In such an event, it is advisable to enlist the services of a professional technician to effect the replacement of the heating elements.

A: It is decidedly not advisable. The curing process may generate noxious fumes. The oven should be installed in a well - ventilated area or the room should be equipped with suitable ventilation facilities to safeguard safety.

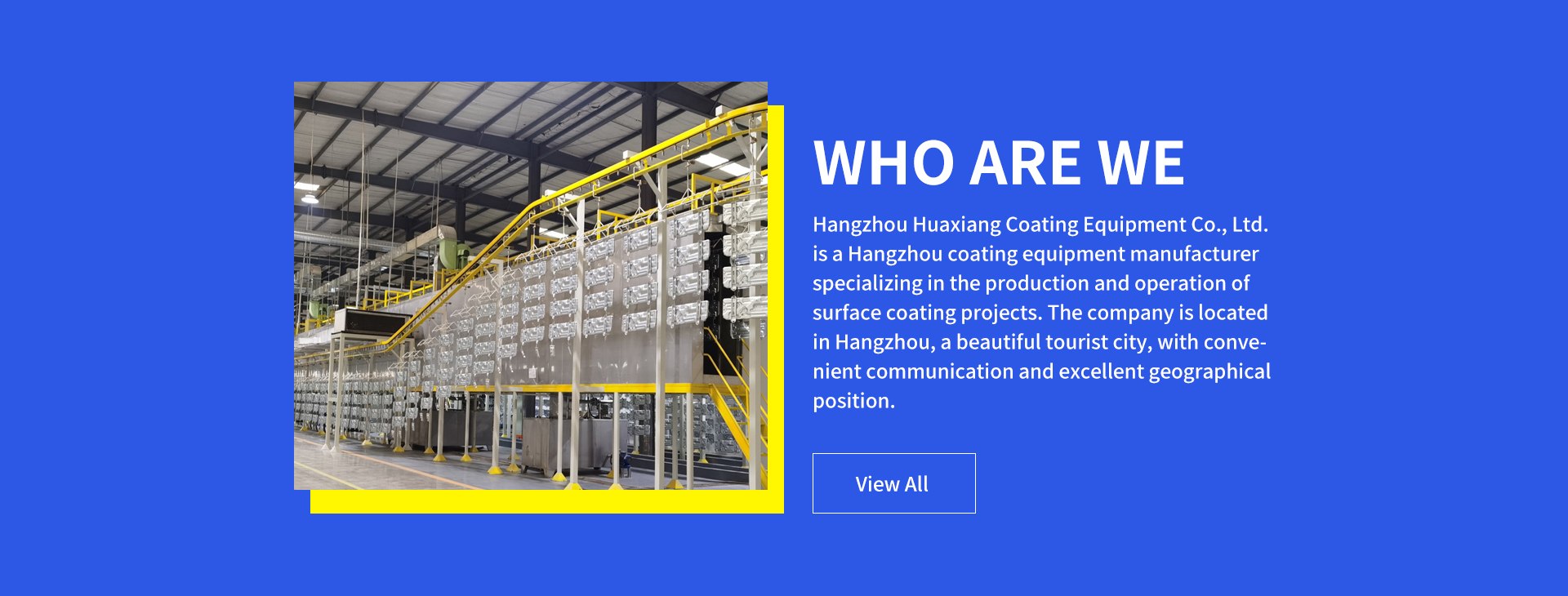

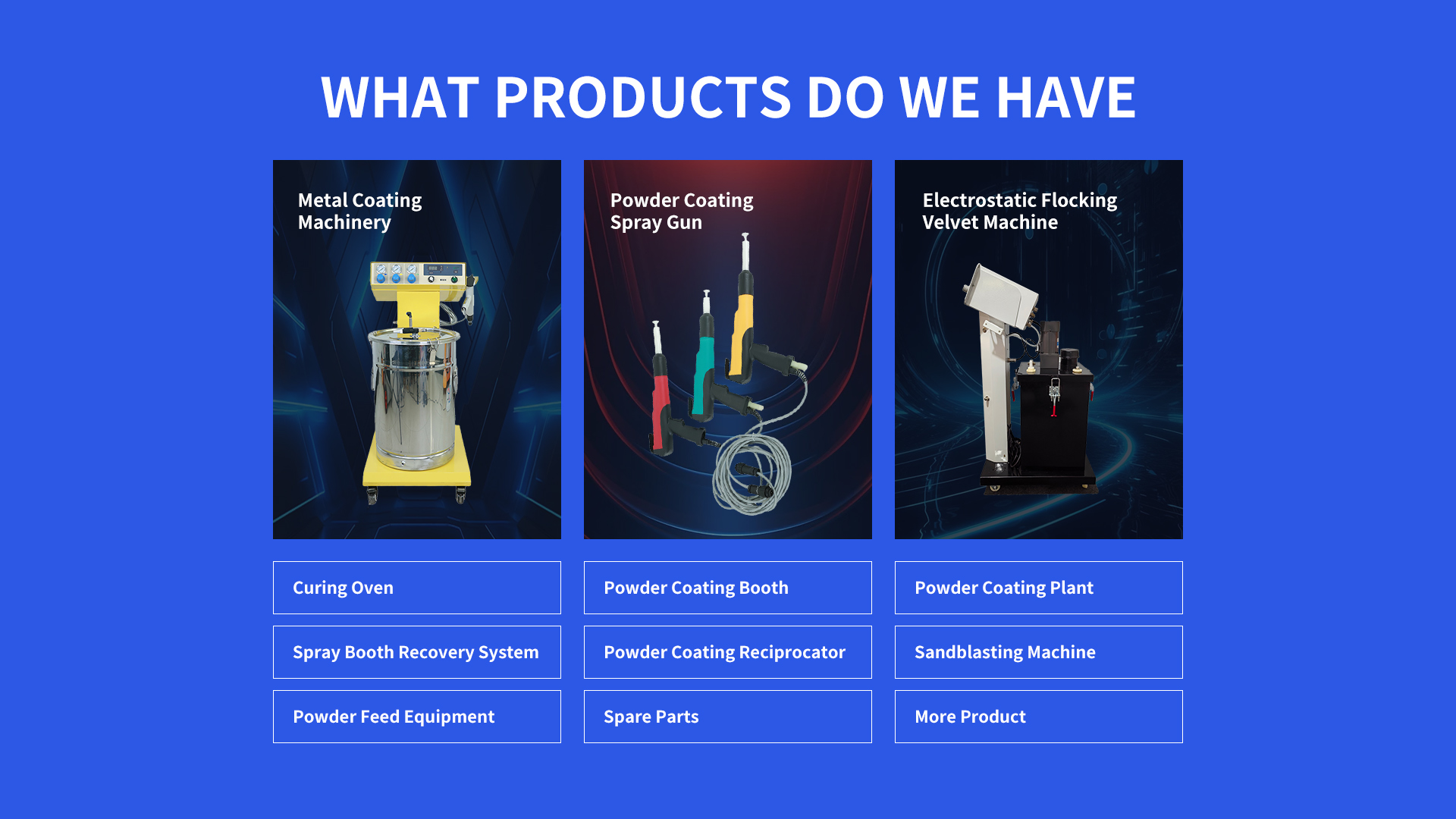

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com